Decision Intelligence for Complex Well Projects

WIISE Flow offers application wellbore solutions through digital twins and AI. We use data from real-time sensors, reservoir and completion wellbore to make high-impact decisions. We provide data-backed insights to reduce investment risk, increase production, and identify the most effective strategy for your operation.

THE PROBLEMS WE SOLVE

Bridging the Gap Between Generic Claims and Field-Specific Value

By moving from assumption-based decisions to simulation-driven intelligence, we empower technical teams and asset managers to select and design the most effective operational strategies with confidence.

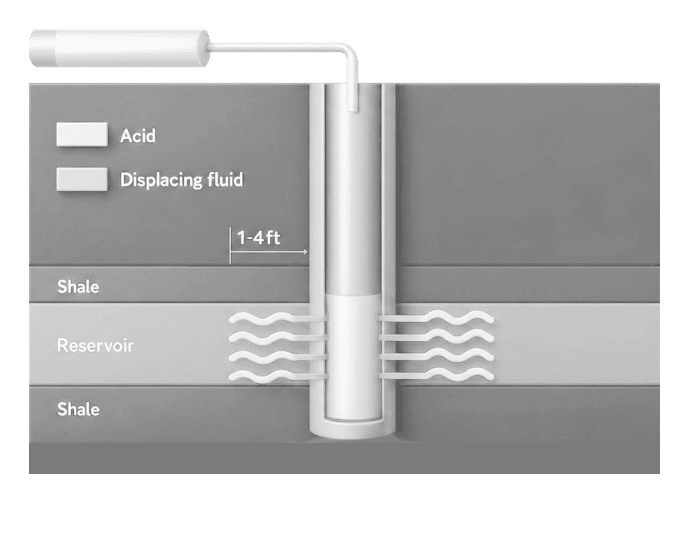

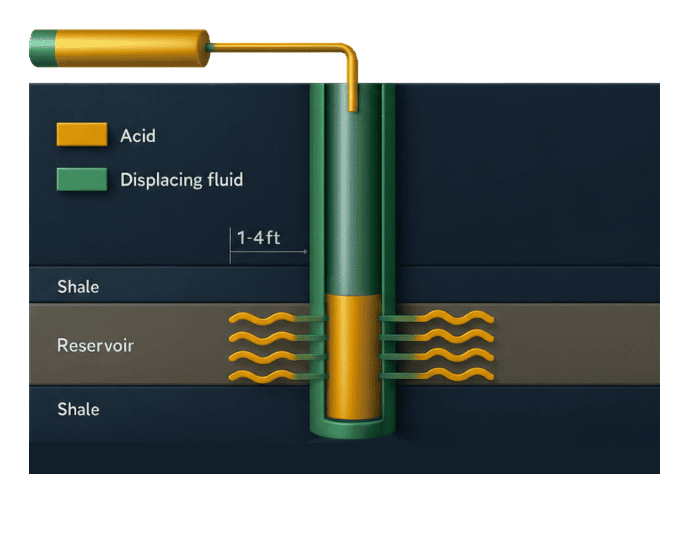

Decision Making In Defining Acid Stimulations

Brazil’s pre-salt carbonates are highly heterogeneous and complex. WIISE Flow is able to mimic all operational acid stimulation techniques through our digital twin. In order to do so, we use your reservoir data, sensor data and completion wellbore data. Your needs are highlighted through case-by-case analysis.

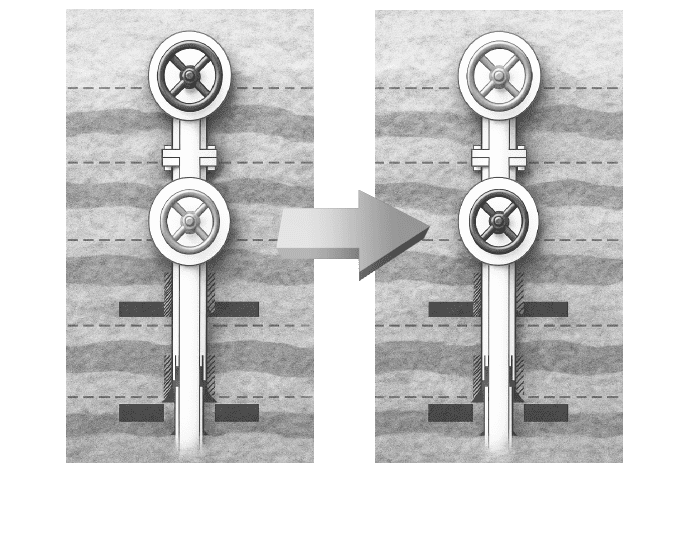

Complex Completions Require Case-by-Case Design

Multi-zone intelligent completions respond to the majority of wells in pre-salt Brazil. WIISE Flow technology through our digital twin precisely identify the productivity zones. We use sensors and completion wellbore client’s data to obtain tailored data-backed insights to deliver real value.

Christmas Tree And Tree Cap Hydrate Dissociation Interventions

Deepwater operations often face hydrate blockages that threaten flow assurance. WIISE Flow has digital twins expertise in dissociation methods—combining depressurization, heating, and chemical injection. Hydrate remediation demands a case-by-case design.

Gas Lift Operating Gains And Challenges

Gas lift remains one of the most flexible artificial-lift methods, especially in pre-salt wells. WIISE Flow simulates digital twins scenarios in valve placement and pressure design. Generic solutions rarely achieve consistent results. Our solution is tailored made for each case resulting in optimal performance.

Improving Late Life Well Integrity: Perforate, Wash And Cement Tool

Sustained casing pressure challenges demand tailored approaches. Perforate, Wash & Cement proves effective, but success depends on careful evaluation of casing condition and cement logs. In complex or extreme scenarios our digital twins provide solutions where generic ones fall short.

Well Design To Mitigate Failures In Control Lines

Gas lift is commonly used in mature Brazilian offshore wells that cannot produce without artificial lift methods. Flow-induced vibration can cause chronic control line failure rendering valves inoperative. Design measures made through our digital twins prevent these failures.

Is Your Asset Strategy Leaving Value on the Table?

Our solution helps you frame the problem by quantifying the upside of your specific project.

Grounded in your field model, our parameter-sensitivity acidizing simulations convert broad service-provider claims into accurate per-well solution. Through our digital twins, our solution will enhance incremental oil and minimize acid volumes.

Simulations applied to PACI completions enable precise evaluation of zonal control strategies, maximizing productivity and reducing uncertainty in completion design.

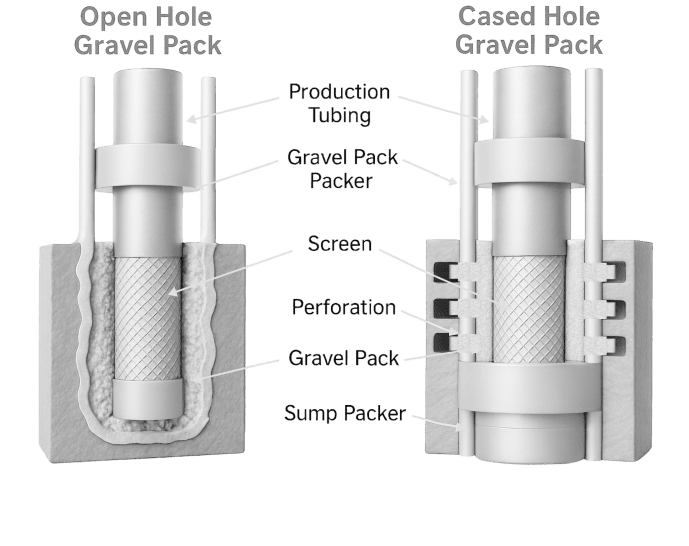

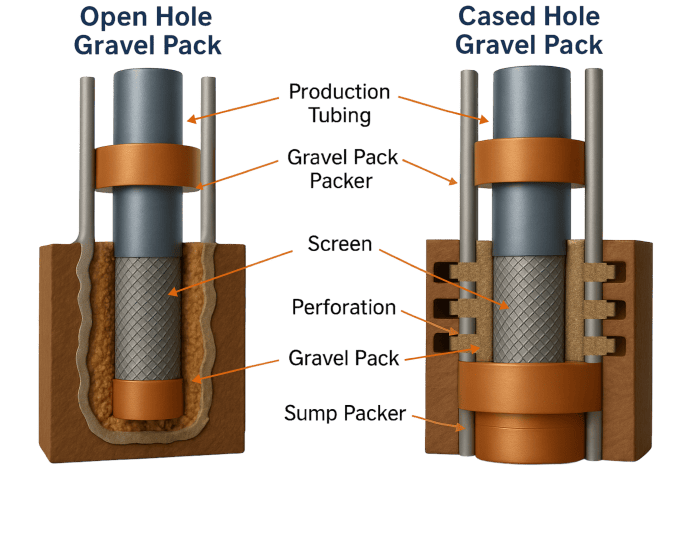

Simulating horizontal open hole-gravel-pack performance enables optimized designs that boost productivity, reduce failure risk, and support more confident completion decisions.

Optimize your Well Projects

Contact our Team to know more about our web consulting services and how we can help increase decision-making and productivity within your Well Projects.

How Our Services Provide More Accurate Solutions

Key Services.

Acid Design Tailored to Reservoir and Completion

We simulate the sensitivity of type and concentration acid, injection rate under your specific reservoir, well completion, and flow conditions. Using your actual completion design, we identify the most effective parameters to maximize wormhole reach, minimize total acid volume, and improve oil recovery.

KPI: Ranking for Confident Execution

We compare acidizing scenarios using real field constraints and deliver decision-ready KPIs such as: incremental oil, post-job skin, and acid saved. Your team can confidently select an enhanced stimulation plan and turn generic service-provider promises into field-specific results.

Sensitivity Simulations for Technical Desicion-Making

In order to evaluate performance across real-world flow contrasts and reservoir heterogeneity, we run targeted simulations under your reservoir specific conditions. Our digital twin allows for testing ICV configuration, placement strategy, and zonal control logic. This enables teams to identify the most effective completion design and reduce operational uncertainty.

KPI: Vendor-Neutral Optimization

Our models produce actionable KPIs—including incremental oil and NPV—to objectively compare intelligent completion strategies. Different service provider technologies are tested against your actual well project. Thus ensuring data-driven design decisions instead of relying on generic performance claims.

Sensitivity & Design Completion

We simulate full-system sensitivities—across well, reservoir, and completion parameters—using your field conditions. This allows us to test OHGP strategies (with or without flow control) under realistic constraints, identifying the most effective design and avoiding guesswork.

Data-Backed Decisions With Performance KPIs

We deliver field-optimized completion recommendations supported by key technical–economic indicators: initial & sustained oil rate, water cut, NPV, and injectivity profiles. Decisions are no longer based on generic promises—but on measurable impact.

Case Studies and Key Articles

How our solution can enhance production and make the most of smart completions

Cases-Backed Acidizing Optimization For Brazil’s Pre-Salt

Per-well optimization can add over 3,000 bpd, cut acid use by 40%, lower skin, and even double productivity versus bullheading by tailoring treatments to each well.

Learn more →Smart Completion Optimization in Offshore Production

In Eagle Ford and Buzios, optimized smart completions can deliver major financial gains—up to USD 70 million annually.

Learn more →Financial Impact of planning Valve Positioning

Strategic use of valve positioning in smart completions shows gains of up to 4 Million USD per well.

Learn more →OUR PROCESS

How we Contribute

We use virtual fully real-world wellbore and reservoir data to quantify performance KPIs. Our solution delivers field-specific insights to support confident, high-impact decisions grounded on sensitivity analysis.

Advanced Wellbore Digital Twins

WIISE solution models the entire wellbore and lower completion using advanced digital twins to provide precise estimations of flow rates and pressures.

To ensure high fidelity, we utilize extensive computational fluid dynamics simulation to calculate accurate pressure drop and flow in wellbore equipment.

This advanced modeling allows complex well operations, such as acidizing, multi-zone production, and completion selection, thus empowering better-informed decision-making.

Advanced Near-Well Reservoir Modeling

Near-well Flow dynamics are captured using high-resolution reservoir models.

WIISE solution seamlessly imports complex geological models from common commercial software, accounting for crucial details like heterogeneous properties and the fully detailed reservoir geometry.

Our near-well models incorporate complex fluid-rock interaction physics. They accurately predicte the outcomes of operations such as wellbore productivity, estimation of damage formation during drilling or maximization wormhole reach in acid treatment.

Fully Coupled Simulation

The true power of our solution lies in the dynamic coupling of the wellbore model and the near-well reservoir simulation.

By computing both simultaneously, the digital twin accurately reflects how the completion and valve positions impact the reservoir, and how the reservoir inflow impacts the well.

This integrated approach creates a predictive digital twin for optimizing any well operation, with proven results in acidizing, formation damage, completion optimization and production estimates.

Our Deliverables

Our team will aid you by providing consulting services tailored to your wellbore and operational needs. Our digital twins mimic both a wide range operations and well completions in order to improve high-impact decisions through simulation-backed insights.

Each engagement includes a decision-focused report with all essential KPIs, sensitivity results, and guidance for confident execution.

We have long term expertise to solve the most challenging well projects not only in pre-salt and deepwater but in any other kind of wellbore operations as well.

Contact our team to explore how we can support your next decision.

Expert Guidance Throughout the Process

During our consulting service, you’ll have direct access to our technical team, ensuring alignment, clarification of results, and support until your objectives are met.

Decision-Focused Technical Reports

Each report is tailored made to your specific case, delivering detailed KPIs and performance parameters that support confident decision-making.

Rodrigo Dias

CEO - WIISE

« The development of our services covers several areas of expertise - computer simulations, optimization, artificial intelligence and software engineering. For WIISE, it is a unique opportunity to contribute to the creation of both a great impact and high technological solutions. »

THE PROBLEMS WE SOLVE

Which WIISE do you belong to?

Discover our solutions

Contact us for more!

Contact us

Find out more about WIISE!

Contact

contact@wiiseflow.comCopy email

Press / Media / Partnership

relations@wiiseflow.comCopy email